行業(yè)需求

Medium voltage inverters generally refer to inverters with voltages of 660V~690V and 1140V. Currently, medium voltage inverters are applied in urban water supply, oil field submersible pumps, injection pumps, beam pumps, main shaft fans, belt conveyors, and coal cutting machines (explosion-proof) in coal mines, achieving good economic and social benefits.

High voltage inverters refer to those with voltages greater than 1140V. Currently, pump loads in industries such as metallurgy, chemical, power, municipal water supply, and mining account for about 40% of the total energy consumption of electrical equipment. Electricity costs can even account for 50% of the water production costs in water treatment plants. This is because: on the one hand, there is usually a certain margin left in the design of equipment; on the other hand, different flow rates are required from the pumps due to changes in operating conditions. With the development of the market economy and the improvement of automation and intelligence, using high voltage inverters for speed control of pump loads not only improves processes and product quality but also meets the requirements for energy conservation and economic operation of equipment, which is a necessary trend for sustainable development. There are numerous benefits to implementing speed control for pump loads.

行業(yè)應(yīng)用方案

Topology 1

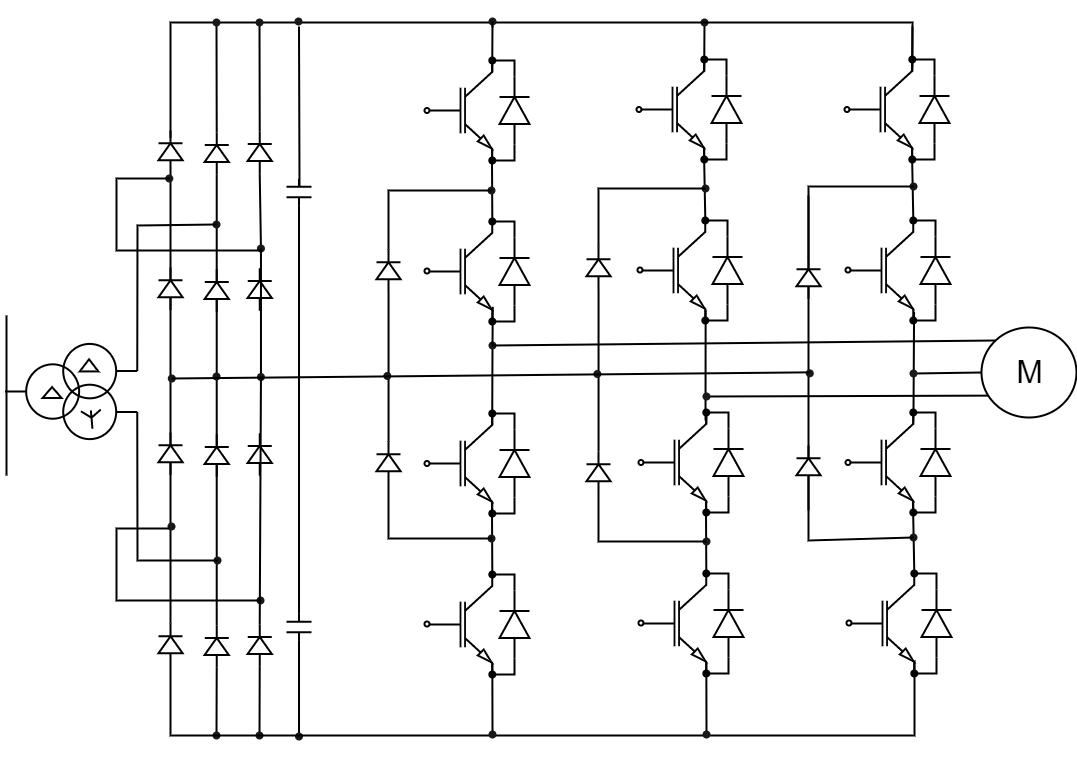

Topology 1:Rectifier + Three-Phase Three-Level Scheme

This topology is primarily used for medium voltage inverters.

Topology 2:Rectifier + Three-Phase Bridge Scheme

Topology 3:Rectifier + H-Bridge Scheme